Mix consisting of PLANOCOLOR GRANULATES and the two component cement based mortar NOCACEM MICRO TERRAZZO. It is suitable for:

• seamless surfaces of thin terrazzo layer 6 – 10 mm

• applications on horizontal surfaces such as:

o external areas, floors, terraces, roof tops, etc.

o internal house areas

o underfloor heating systems

• application on various substrates such as:

o concrete or screeds

o existing coverings such as tiles, natural stones

Refer to the Technical Data Sheets Safety Data Sheets of the products listed here before the final selection of the mix for each application.

• Form: Powder & latex

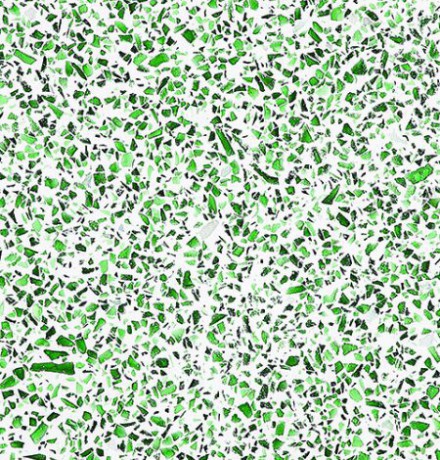

• Color: See photo

• Chemical substance: Portland cement, aggregates, special additives

• Specific gravity of the mix: 2,1 ± 0,1 kg/L

• Dry density of the mix: 2,0 ± 0,1 kg/L

• Workability: 45 – 60 min / 20°C

• Walkability: 5 – 6 hours

• Application temperature: from +5°C up to +35°C

The polished micro-terrazzo coating MT 23 consists of a dry mix as follows:

INGREDIENT QUANTITY PER 100 kg OF DRY MIXTURE

NOVACEM MICRO TERRAZZO 50 kg

PLANOCOLOR GRANULATES RC GLASS 90 920 GREEN 50 kg

NOVACOLOR DESIGN 9003+10% 5,88 pcs

Depending on the type of aggregates mixed with NOVACEM MICRO TERRAZZO, the 28 days cured coating will develop a compressive strength that falls within the range of 35 to 50 Mpa. Additional information you may find at the Technical Data Sheet of NOVACEM MICRO TERRAZZO.

Substrate preparation:

Cement-based substrates have to be compact, level, clean, free of grease, oil, laitance and any substances which may compromise the adhesion of NOVACEM MICRO TERRAZZO. The minimum flexural strength shouldn’t be less than 1,5 N/mm2 and the minimum compressive strength at least 25 N/mm2. Existing cracks on the substrate should be bonded with the fluid epoxy resin EPO FLUID. On the still fresh EPO FLUID surface, scatter PLANOCOLOR GRANULATES S 500 silica sand or similar in order to create a uniform mineral surface. Absorbent substrates should be primed with PLANOPRIMER in order to increase the adhesion and provide a sealed substrate. Substrate of reduced strength should receive consolidation treatment by means of NOVAPRIMER or WATER PRIMER EPX and full coverage with the sand PLANOCOLOR GRANULATES S 500, by scattering on the still wet primer surface.

Existing floor coverings such as ceramic tiles, gres porcelain, marble, terrazzo, etc. are required to be firmly attached on the substrate. These types of substrates also have to be clean and free of laitance or any substance which will compromise adhesion on them. If required, use for cleaning one of the following products: ALCALINE CLEANER or ACID CLEAN or ACID CLEAN TURBO depending on the type of stain, and rinse well with water. Prime the clean and dry covering with PLANO CONTACT. For external and wet area applications, the substrate has to be waterproofed first by using SC ELASTIC or SC 200 PENETRATE.

Preparation of the mix:

In the bucket containing the powder empty the recipients containing the PREMIUM LATEX and the pigments in liquid form NOVACOLOR DESIGN, according to the desired color, of the relevant PLANOCOLOR MICROCEMENT color chart. According to the required workability for every 1kg of PREMIUM LATEX 1-1,5L of clean water must be added. Mix by means of electrical stirrer for at least 3 min until you obtain a uniform mix free of lumps. Then, while stirring add the granulates at a rate depending on the aesthetics requirements of the application. The mix has to be used within 45 – 60 min after mixing in normal conditions. After this time don’t try to soft the mix by adding water.

Application:

The laying of the mortar follows the general rules applicable to low thickness floor coatings. Apply the fluid mixture on the substrate in one layer and of thickness 2 – 3 times the maximum aggregate grain size by using a flat plastic or metal trowel. Then smooth the surface.

Depending on the composition of the mixture and the conditions of application the grinding process begins after 24 – 48 hours. For the mechanical and abrasive agents always follow the manufacturer’s instructions such as suitability, rotational speed, wet or dry processing.

Small air bubbles developed in the mortar during mixing, may appear in the form of pinholes or small cavities, on the surface during grinding process. Filling of these holes is recommended to take place during initial grinding at intermediate stage when all embedded aggregates appear uniformly on the surface. After thoroughly cleaning the entire application area from the dust and abrasive residues by rinsing with water and sucking the waste water, smoothing can be done by using NOVACEM MICRO TERRAZZO mix without the addition of granulates. Alternatively, but only for indoor applications, you can use PLANOFINISH CRYSTAL to fill the pinholes.

Expansion joints:

The expansion joints incorporation depends on the use of the surface and the dimensions of the area. In internal areas every 5 – 7 linear meters and in external areas every 5 linear meters.

Recommendations:

• Apply only on solid and properly primed substrate

• Do not add water in quantity higher than the recommended and do not add water when the mixture starts to set

• Do not cover or apply the product over existing expansion joints of the substrate

• Do not apply the mortar on substrates with rising damp or in total water immersion without substrate waterproofing

• Do not add cement, gypsum, lime or other binders which may influence the properties of the mortar

• Don’t apply the mortar on substrates and/or areas when temperature less is than +5°C or higher than +35°C

• Do not apply directly over anhydrite screeds, metal or flexible substrates with high deformability and intense vibration

• Do not apply upon deformable substrates, surfaces subjected to vibration

• Do not apply upon non-absorbent substrates such as metal, glass, old ceramic tiles and mosaics without applying appropriate primer

• Application must be done by professional applicator

Refer to the Technical Data Sheets as well as the Safety Data Sheets of the products listed here.

Consumption:

The consumption depends on the mixing ratio of the granulates and the cement based binder NOVACEM MICRO TERRAZZO.

THICKNESS* NOVACEM MICRO TERRAZZO PLANOCOLOR GRANULATES RC GLASS TOTAL

MEASUREMENT UNIT mm kg kg kg/m²

DRY MIX RATIO 50% 50% 100%

SPECIFIC GRAVITY 22kg/cm³ 6 6,6 6,6 13,2

8 8,8 8,8 17,6

10 11,0 11,0 22,0

THICKNESS* NOVACEM MICRO TERRAZZO PLANOCOLOR GRANULATES RC GLASS TOTAL

MEASUREMENT UNIT mm kg kg kg/m²

DRY MIX RATIO 30% 70% 100%

SPECIFIC GRAVITY 22kg/cm³ 6 3,96 9,24 13,2

8 5,28 12,32 17,6

10 6,6 15,4 22,0

THICKNESS* NOVACEM MICRO TERRAZZO PLANOCOLOR GRANULATES RC GLASS TOTAL

MEASUREMENT UNIT mm kg kg kg/m²

DRY MIX RATIO 70% 30% 100%

SPECIFIC GRAVITY 22kg/cm³ 6 9,24 3,96 13,2

8 12,32 5,28 17,6

10 15,4 6,6 22,0

*Thickness before grinding

Cleaning:

Tools, buckets, tiles etc. can be cleaned with fresh and clean water as long as, NOVACEM MICRO TERRAZZO is still fresh. After hardening occurs, cleaning can take place only by mechanical means.

Legal notes:

The technical data and recommendations contained or listed are the result of laboratory measurements, of our current knowledge and experience. All the above-mentioned information and specifications should in any case be considered as indicative.

The Company makes every effort to ensure the accuracy of the information provided herein. Product specifications, prices and availability are subject to change without notice and may differ from those shown.

Due to printing and application procedure, the colors and their final appearance presented here and in every catalogue or brochure, should be considered as indicative.

In practice, variations in materials, substrates and on-site implementation conditions are such that no warranty can be given or implied as to the merchantability or suitability of the materials for a particular purpose and for the exact conditions of each project. Anyone interested of using the product must be sure beforehand that the product is suitable for the intended use and in any case, the user is solely responsible for any consequences due to the use of the product. Among other things, the Company is not responsible for any normal wear or tear from environmental or other inappropriate conditions. We reserve the right to revise or change the data herein without prior notice.

Restrictions and disclaimers apply to the extent permitted by applicable law.

The Company has a Technical Support Department, which is the only one responsible for providing technical advice and solutions to deal with problems. Requests to the Technical Support Department are addressed and answered, only in writing.

For the latest and valid version of the Technical Data Sheet, the user of the material must refer to our website www.novamix.gr.